Great Lakes Industrial Knife is recognized throughout the Plastics Industry as a leading manufacturer of high quality Granulator and Pelletizer knives. Performance engineered, our Granulator and Pelletizer knives meet or exceed OEM specifications.

- High-Tech Metallurgy

- Match ground sets

- Razor edge technology

- Expert regrind/sharpening service

- Made in the USA

For a quote, Call (888) 665-1200, Fax (330) 665-1204, Contact Us, or Fill out our quote form today!

Product List

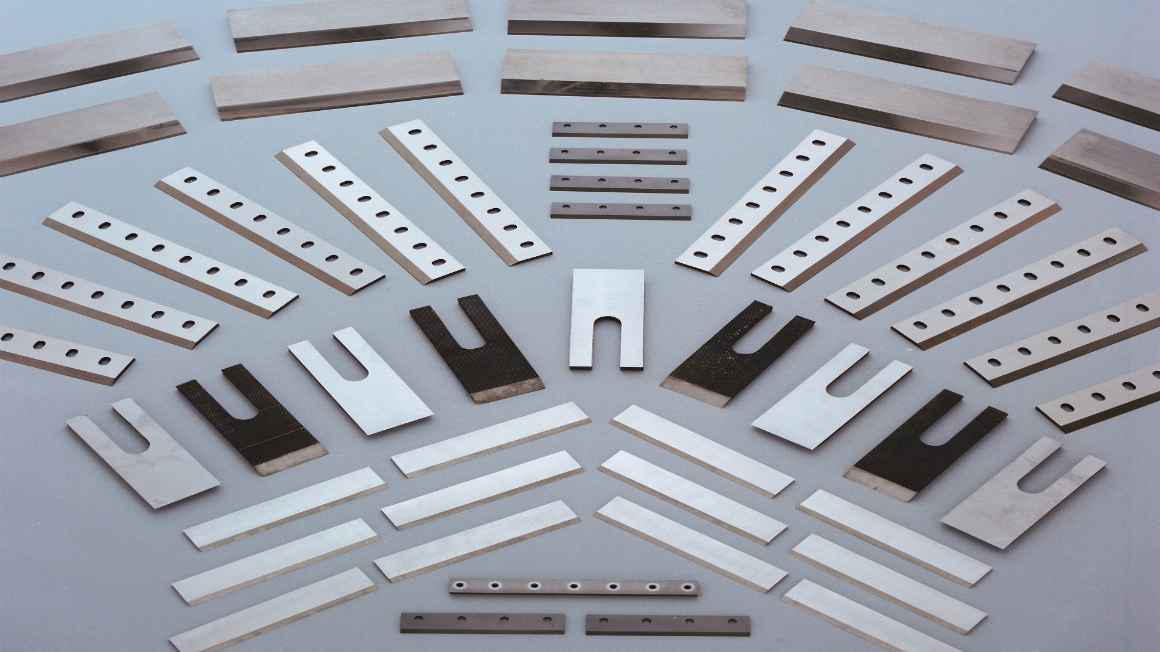

Custom Machine Knives Find out more

Great Lakes Industrial Knife is a leading manufacturer of machine knives and blades spanning a multitude of industries and applications. Proudly made in the USA by skilled engineers and machinists, machine knives and blades from Great Lakes deliver the performance and durability you need to keep your plant running. We specialize in quick-turn manufacturing and can produce knives in just weeks. Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your various machine knife challenges.

Our Machine Knives are precision manufactured to extremely close tolerances.

- Short lead time on custom orders

- Expert regrind service

- Made in USA

- Proven extreme condition materials for maximum wearability, toughness and performance

Performance Engineered Metallurgy

- Alloy tool steels

- D-2 High carbon/High chrome tool steel

- High speed steels

- Powdered metals, CPM 10V®, CPM M4®

- Composite tool steels

- High performance stainless steels

- Solid Stellite®

- Inlaid Stellite®

- Zirconia ceramics

- Tungsten Wc & Titanium carbide hard metals TiC Ferro-Tic®

- ICE™ Inlaid Carbide Extreme

Stellite® is Registered Trademark of Deloro Stellite Company Inc.

Ferro-TiC® is a registered trademark of Pacific Sintered Metals

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Request a Quote

Request a quote form

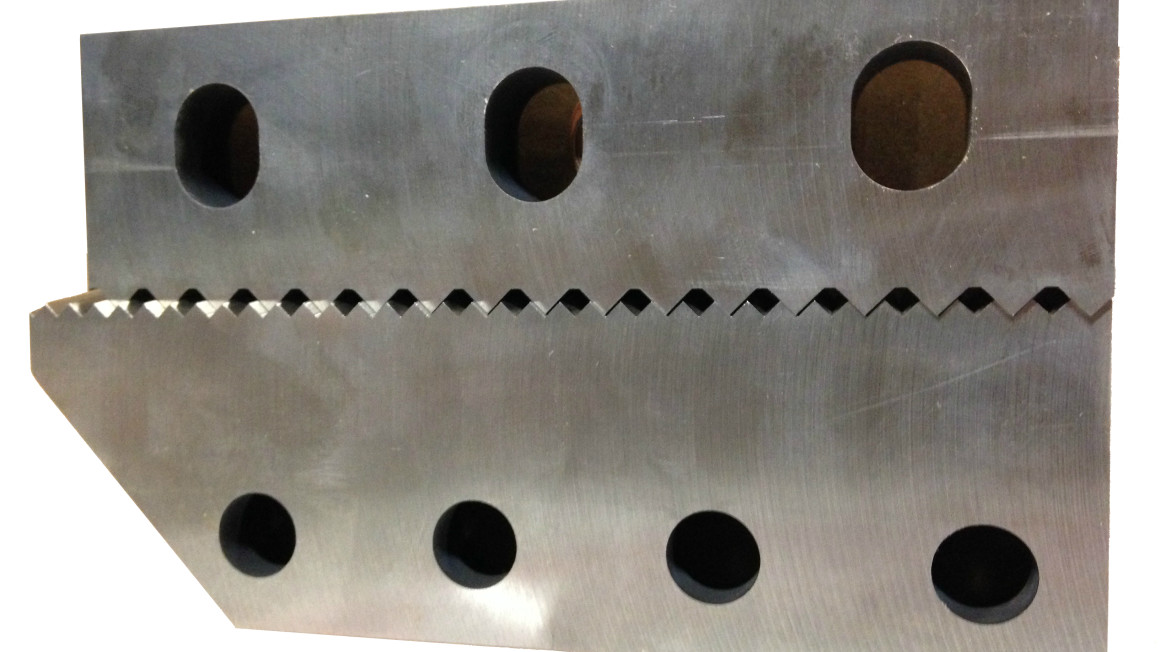

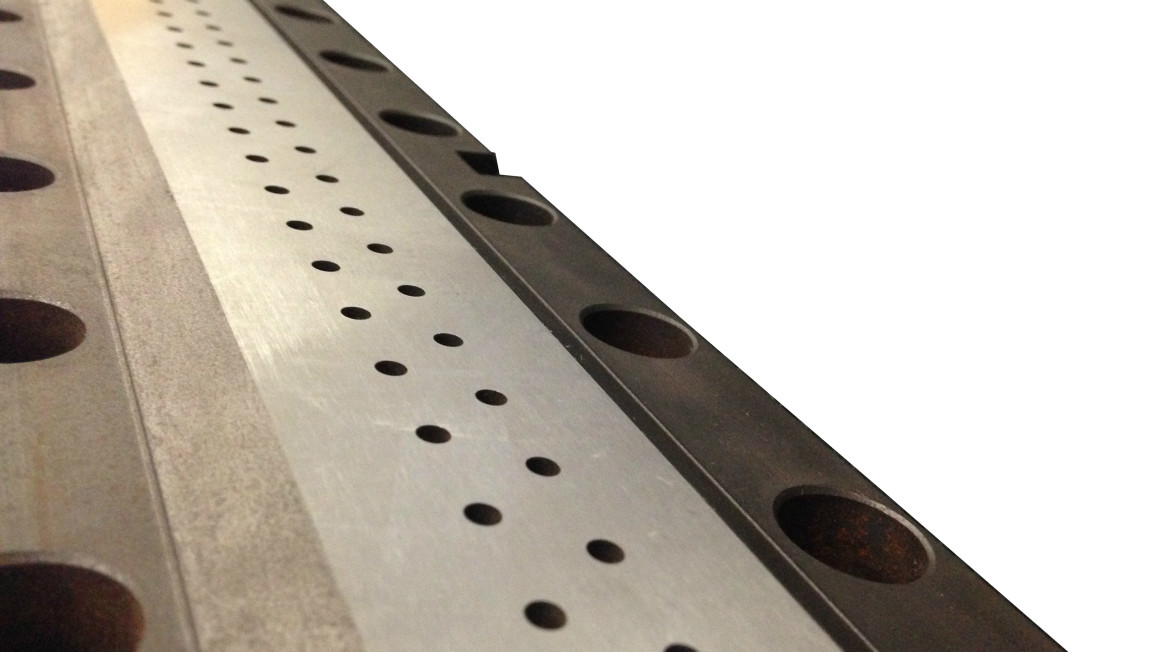

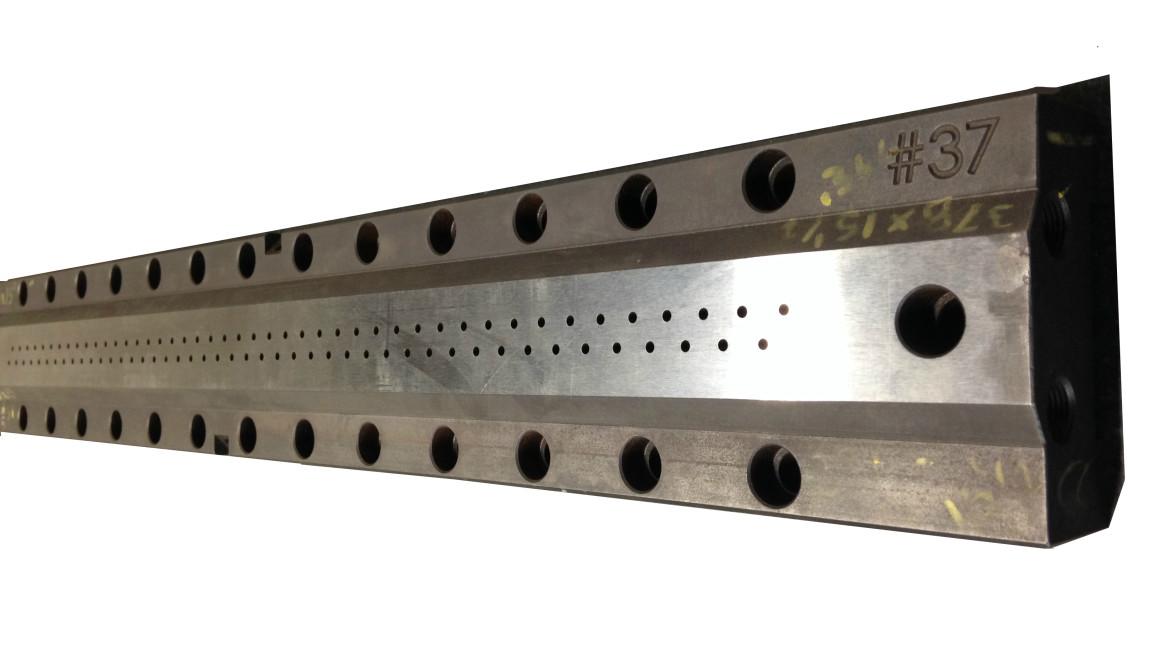

Dicer & Dicer Bed Knives Find out more

Great Lakes Industrial Knife manufactures dicers and dicer bed knives for all machine makes and models including Henion Dicers, Bolton Dicers, Sagitta Dicers, Cumberland Stair Step Dicers, and Stacked Disc Dicers right here in the USA! Our skilled engineers and machinists can manufacture or repair virtually any type of dicer. Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your dicer challenges.

Rotary Dicers to standard sizes 1/8″, 1/32″ and 3/32″ tooth in both cube and octahedron as well as custom sizes.

Our Dicers are CNC manufactured to extremely close tolerances.

- Precision manufactured matched sets

- CNC sharpening to OEM specs, 0.0005″ concentricity

- Complete MIG weld tooth repairs

- Exact tooth profile – mirror finishes

- Tungsten carbide surface coatings

- Bed knives and platten bars

- Proven extreme condition materials for maximum wear-ability, toughness and productivity

Performance Engineered Metallurgy

- High wear alloy tool steels

- High speed tool steel

- Powdered metals, CPM 10v®, CPM M4®

- ICE™ Inlaid Carbide Extreme

Stellite® is Registered Trademark of Deloro Stellite Company Inc.

Ferro-TiC® is a registered trademark of Pacific Sintered Metals

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Request a Quote

Request a quote form

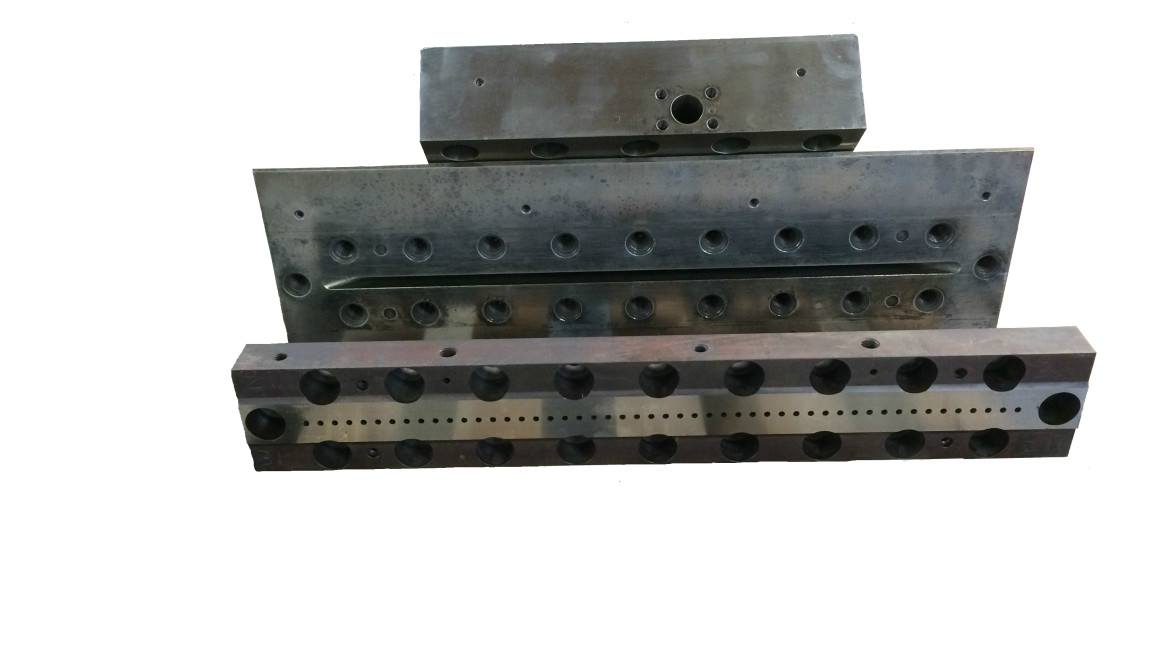

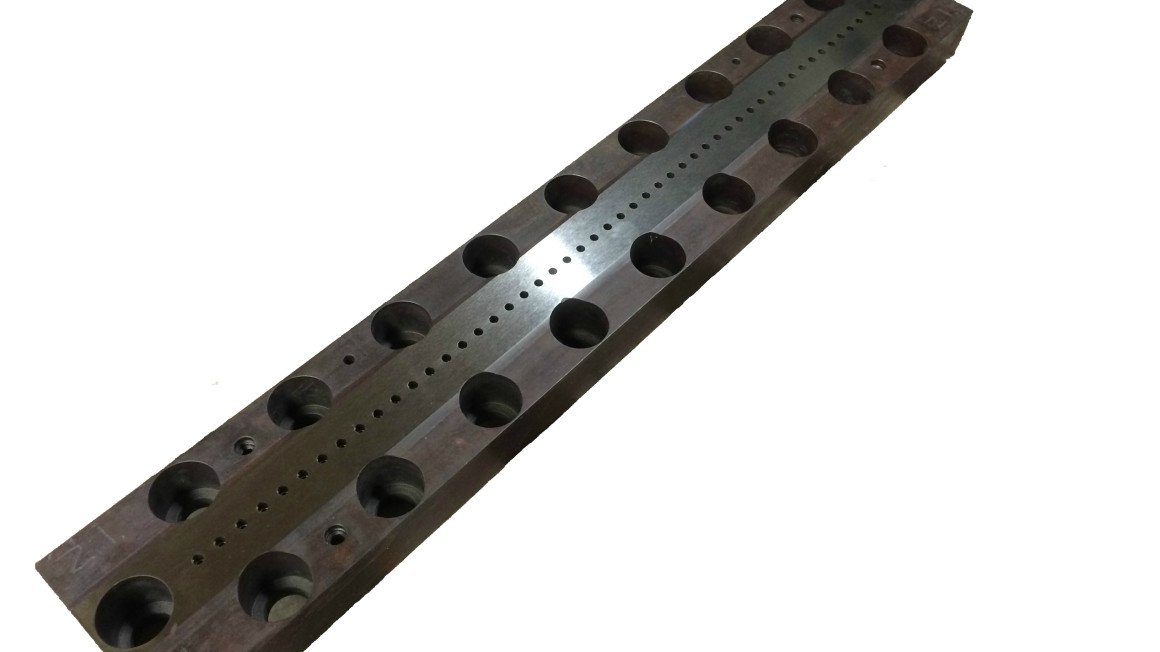

Extrusion Dies Find out more

Great Lakes Industrial Knife manufactures and repairs extrusion dies right here in the USA for the plastic compounding industry. Our skilled engineers and machinists can make or repair virtually every extrusion die configuration. Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your extrusion die challenges.

- Precision manufactured and machined to OEM specifications or custom design

- CPM 10V, CPM 15V, stainless steel S90V, are just a few of the powdered metals used

- Stellite hard facing and weld repair

- Proudly made in the USA by skilled machinists

Request a Quote

Request a quote form

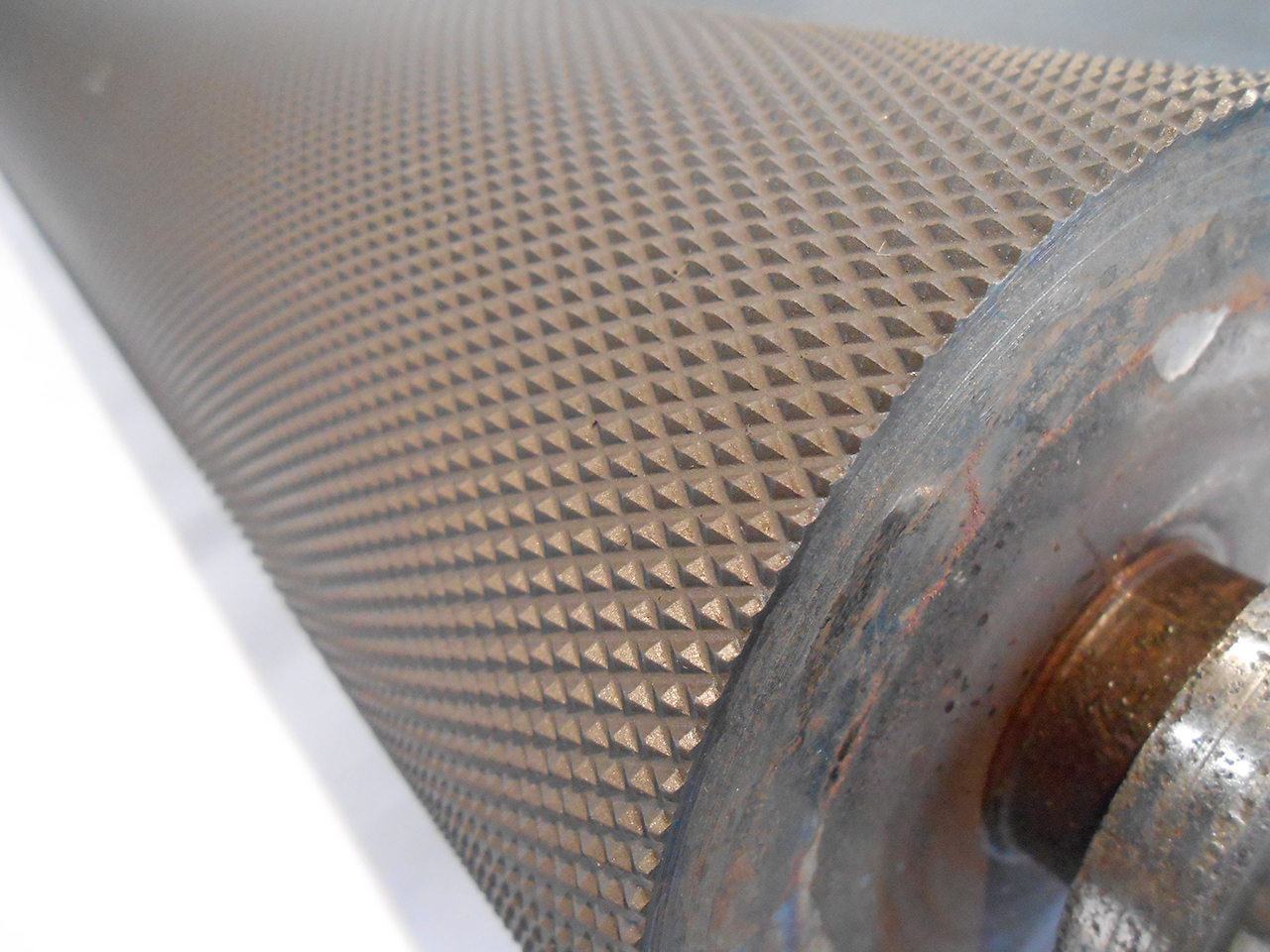

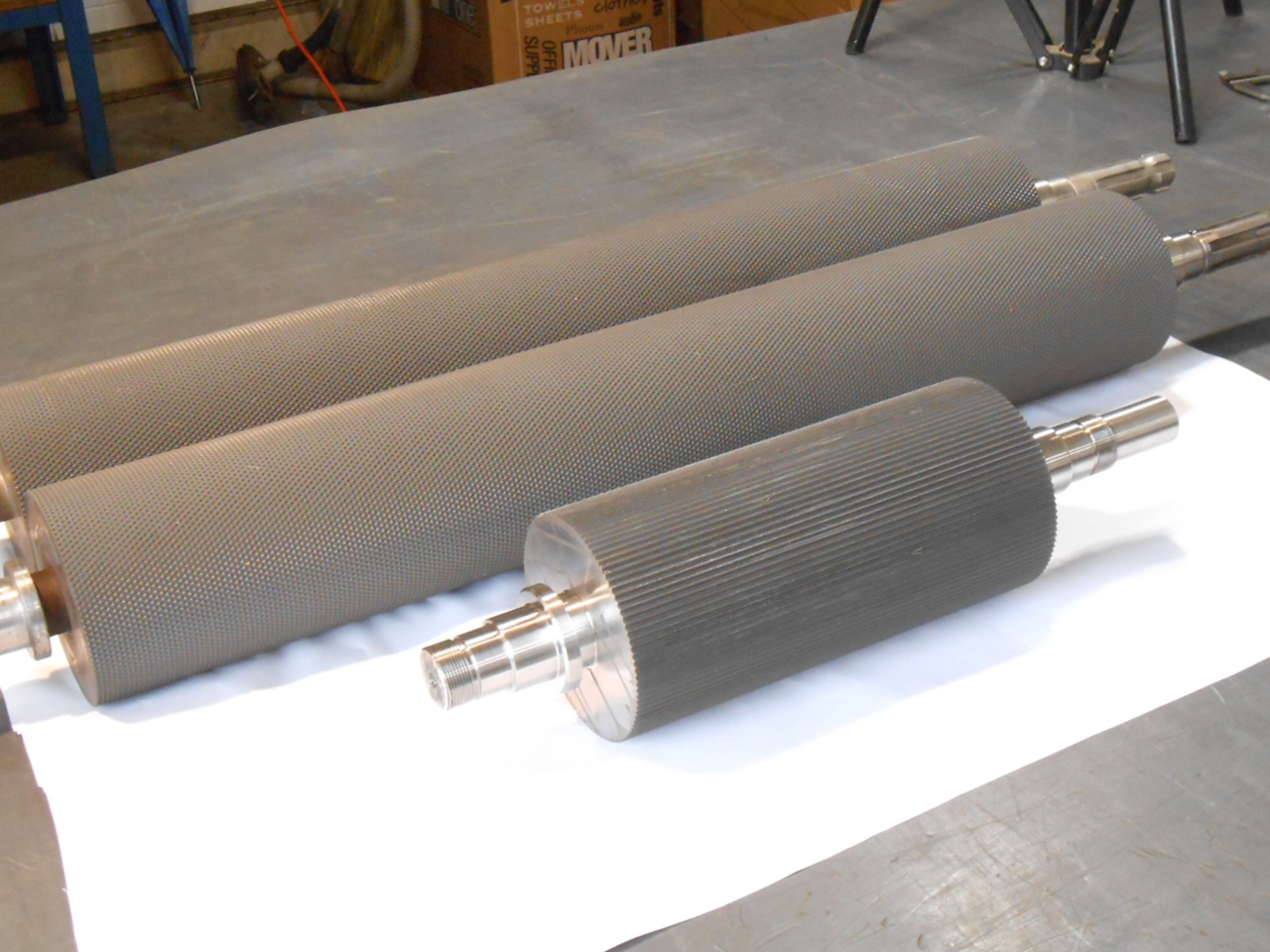

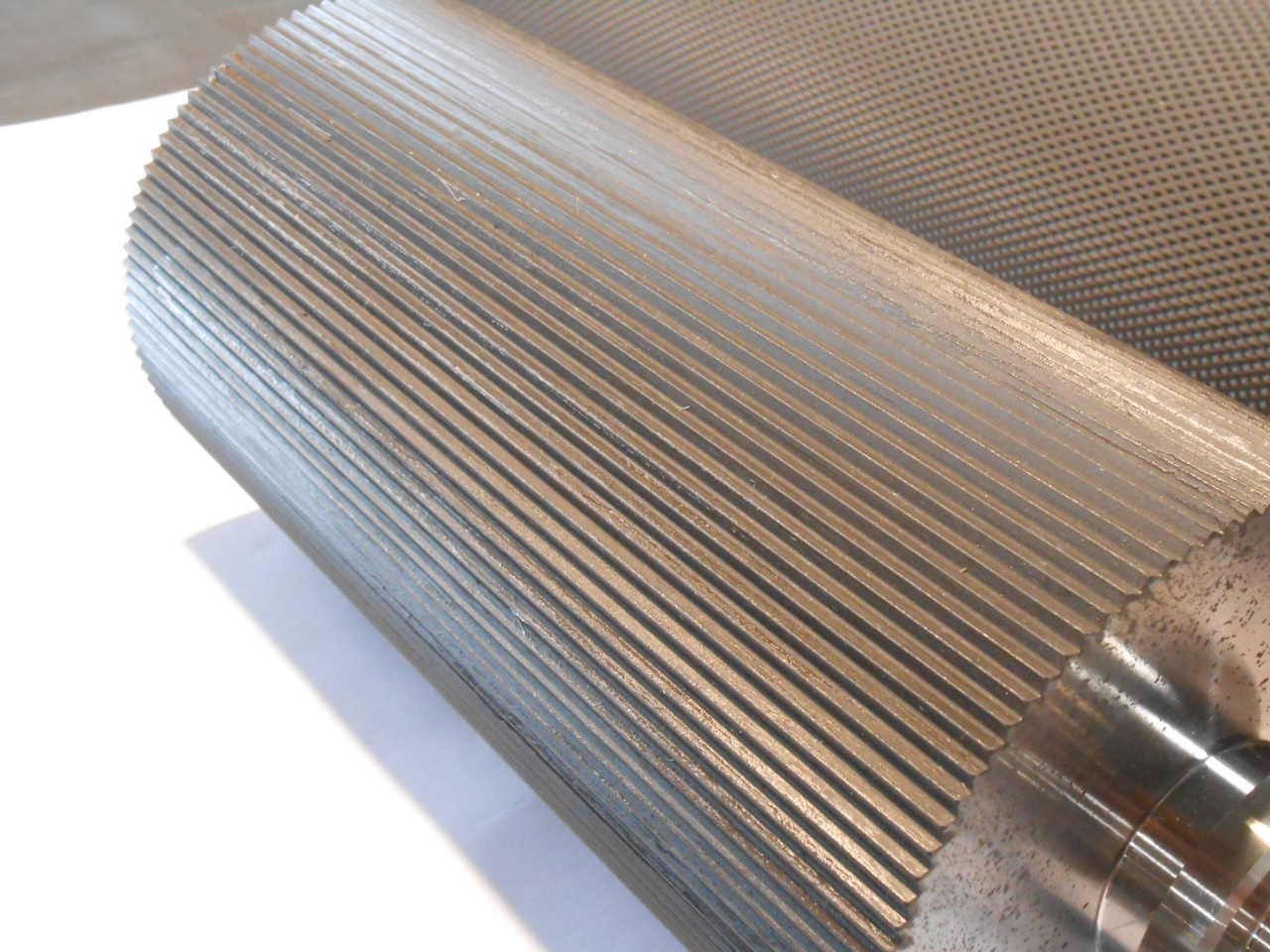

Feed Rolls / Pull Rolls Find out more

Great Lakes Industrial Knife manufactures and repairs feed rolls and pull rolls for all virtually all strand pelletizer makes and models right here in the USA. Our skilled engineers and machinists can make or repair virtually every feed roll configuration.

Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your strand pelletizer feed roll challenges.

Request a Quote

Request a quote form

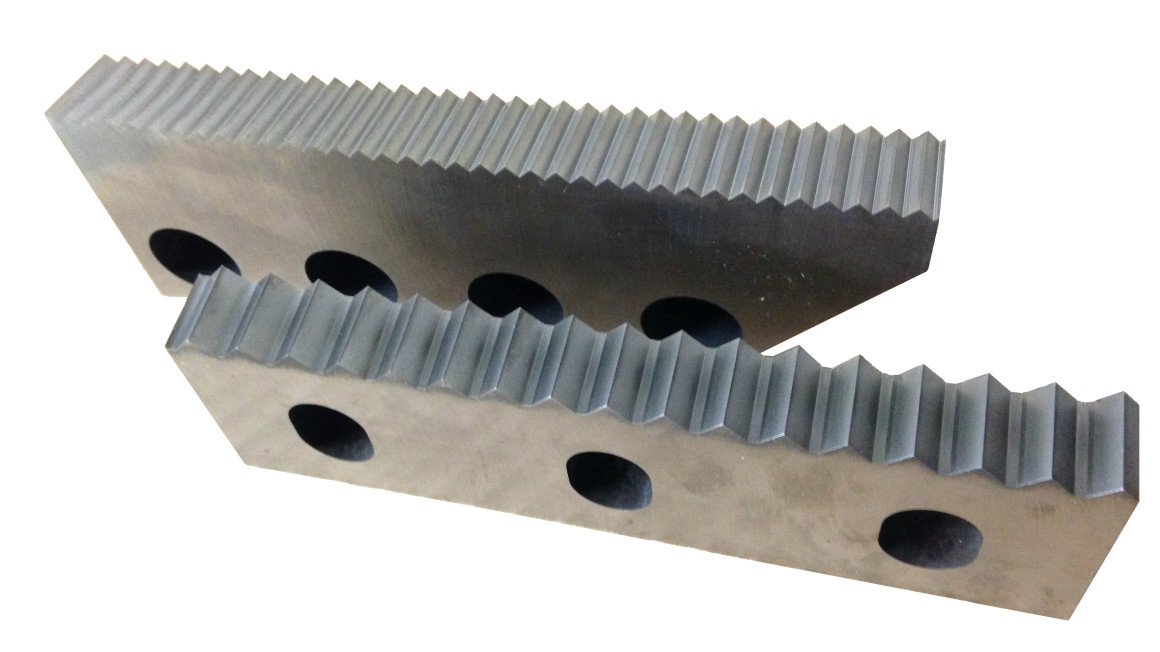

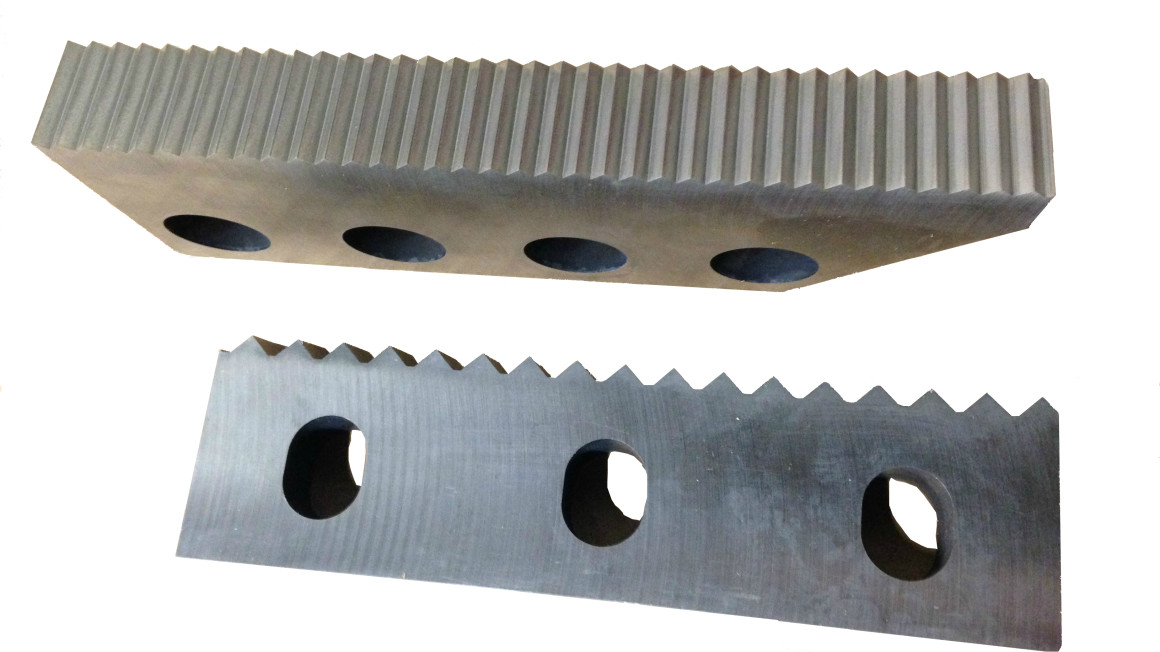

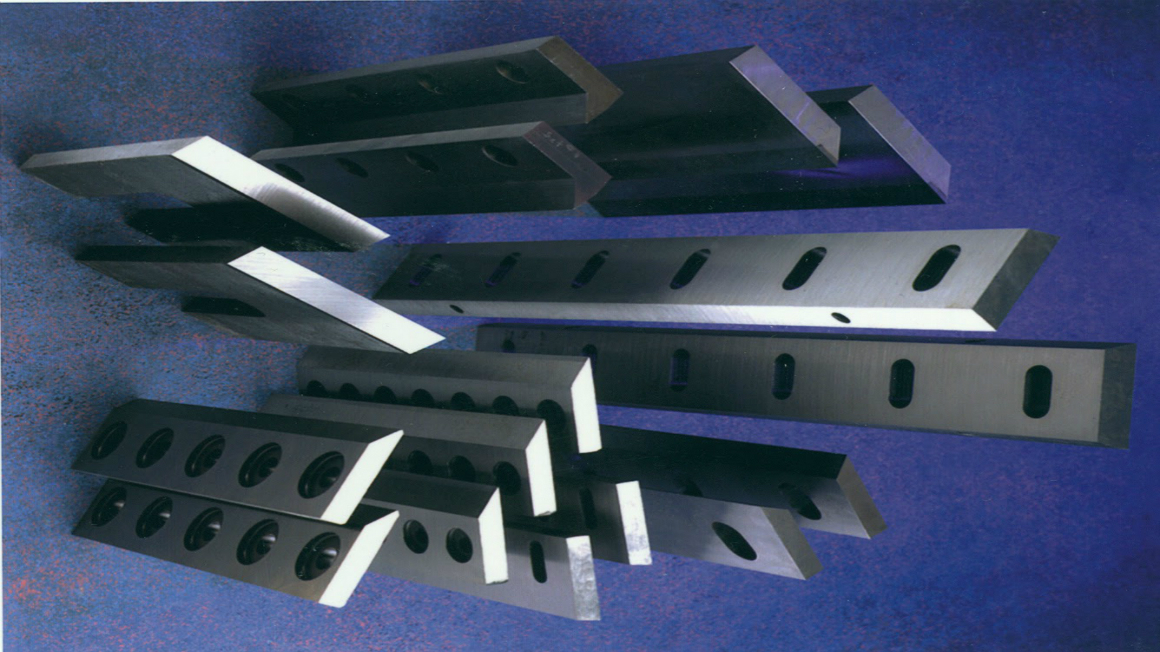

Granulator Knives / Granulator Screens Find out more

Great Lakes Industrial Knife manufactures granulator knives and screens for all machine makes and models including Cumberland, Conair, Nelmor, Ball & Jewell, Foremost, Granutec, Mitts & Merrill, Rapid, Taylor-Stiles, Precision Airconvey as well as many more. Need a set of knives quickly that no one stocks? Trust Great Lakes Industrial Knife to rapidly manufacture granulator knives in just 6 to 8 weeks in our Akron, Ohio facility. Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your granulator knife challenges.

All of our granulator knives are precision manufactured to extremely close tolerances.

- Tungsten Carbide replacement knives

- Precision Airconvey granulator / in-line cutter PAC 78 & PAC 811

- Hooked rotor knives

- Bed knives

- Burr-free, razor sharp cutting edge

- Expert in-house sharpening service, match ground sets

- Tungsten carbide surface coating

- Rotor & shaft repair/balancing

- Computerized inventory control

- Stock delivery on standard knives

- Proven extreme condition materials for maximum wearability, toughness and production

Performance Engineered Metallurgy

- High wear alloy tool steels

- D-2 High carbon/High chrome tool steel

- Powdered metals, CPM 10V®, CPM M4®

- Composite tools steels

- High performance stainless steels

- Solid Stellite®

- Inlaid Stellite®

- Zirconia ceramics

- Tungsten Wc & Titanium carbide hard metals

- TiC Ferro-Tic®

- ICE™ Inlaid Carbide Extreme

Stellite® is a registered trademark of Deloro Stellite Company Inc.

Ferro-TiC® is a registered trademark of Pacific Sintered Metals

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Request a Quote

Request a quote form

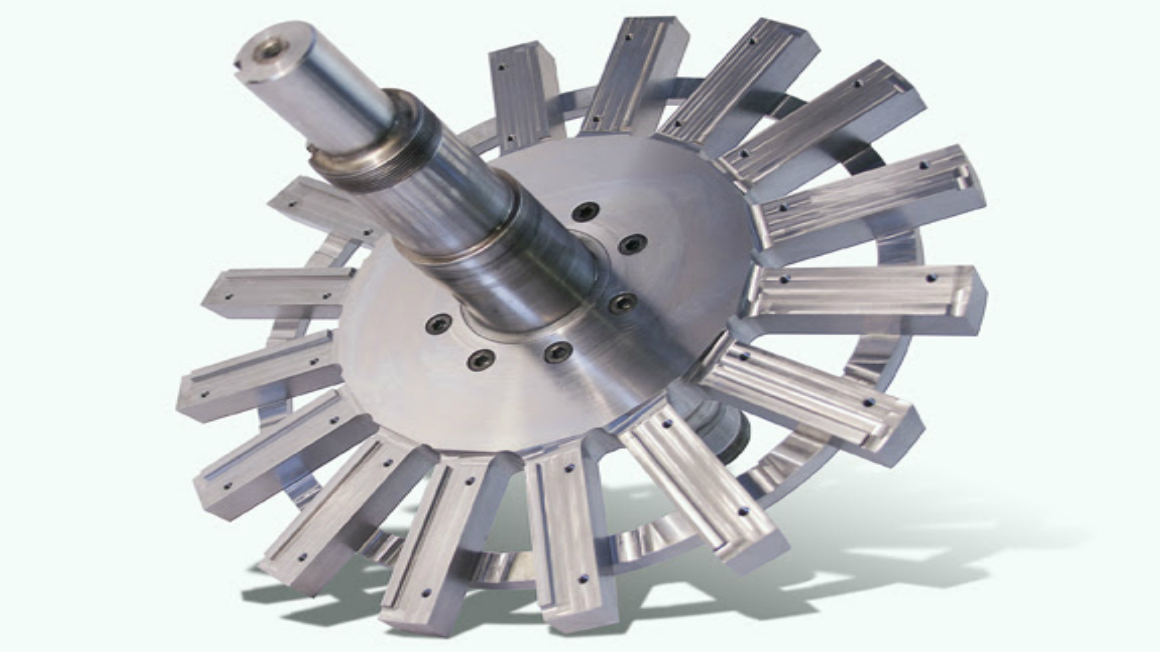

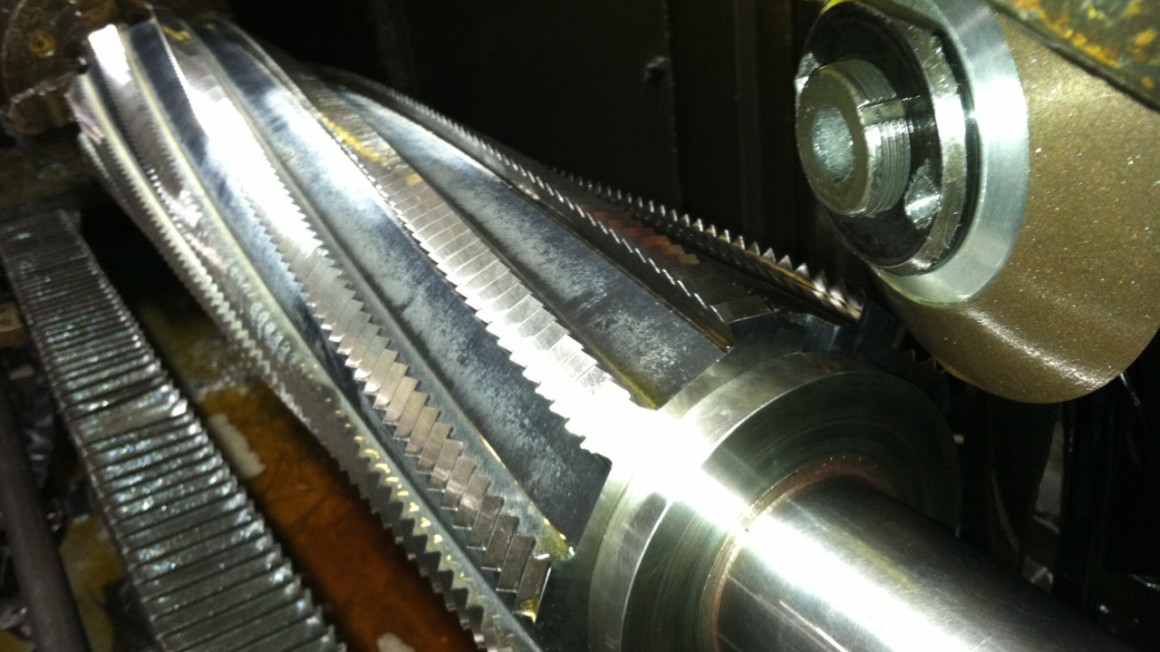

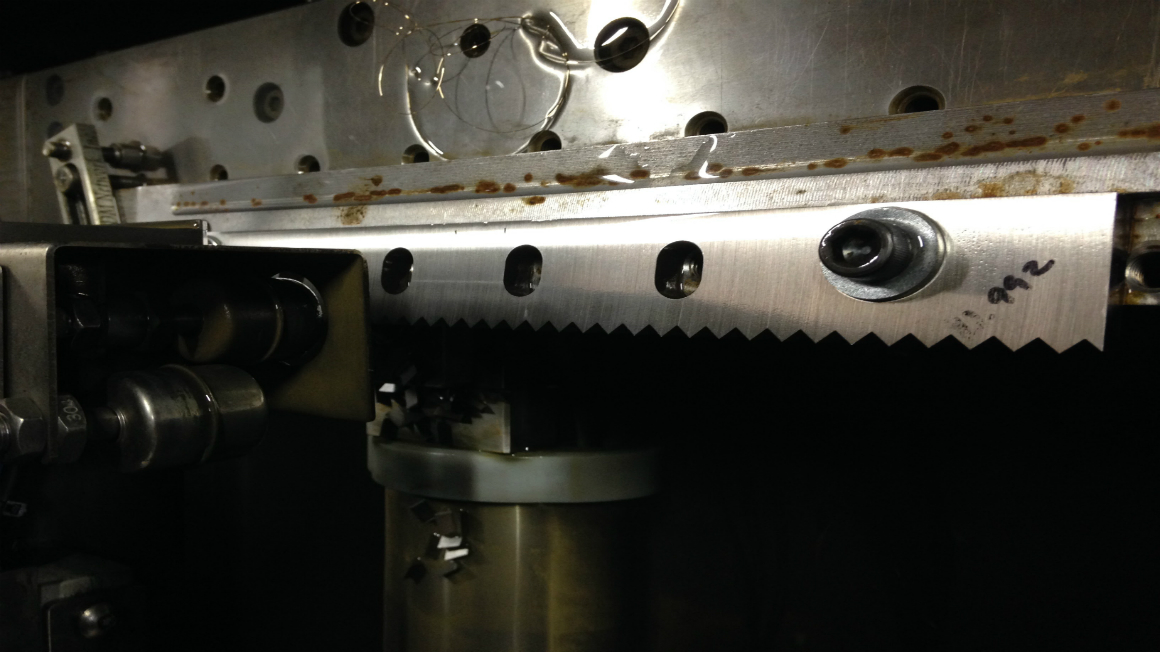

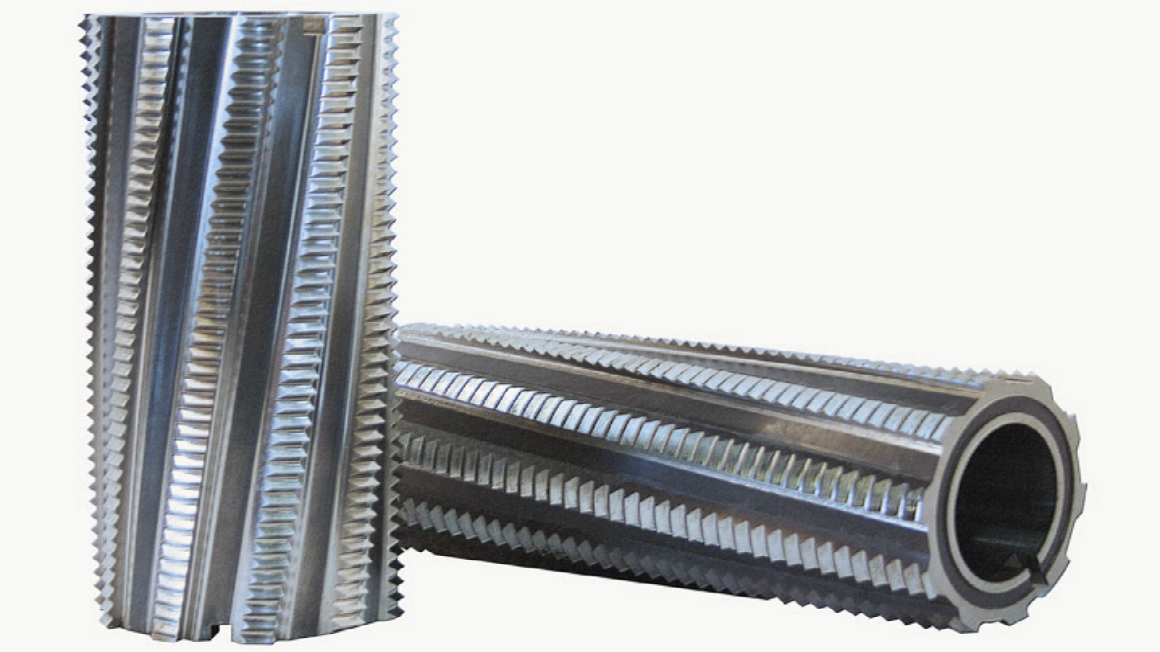

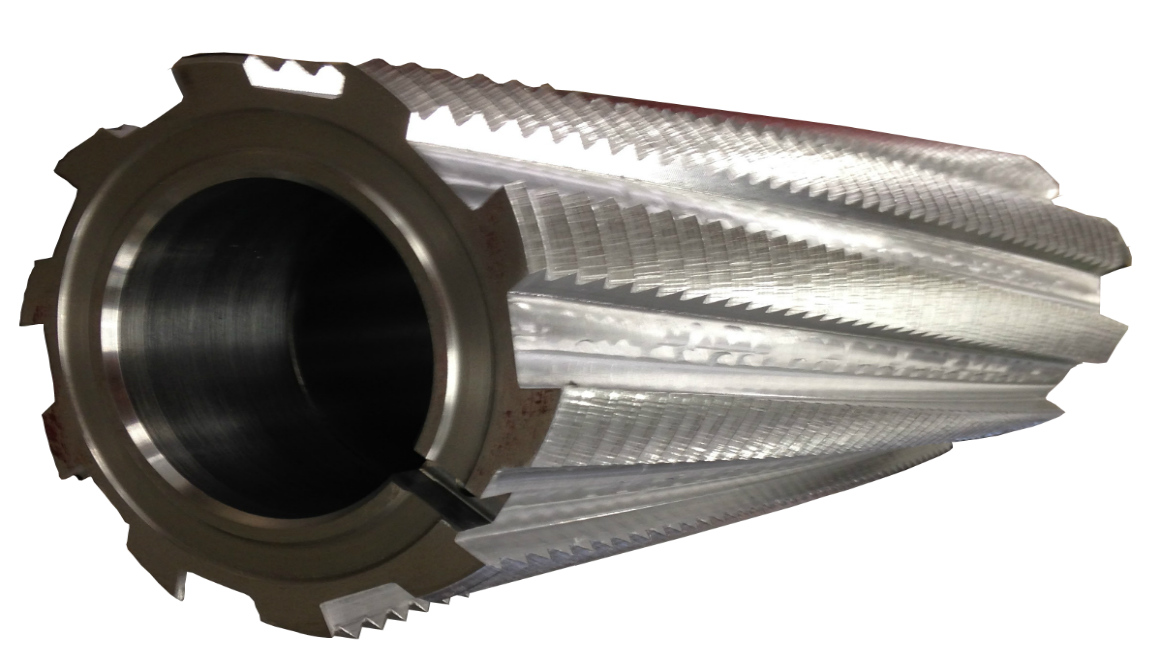

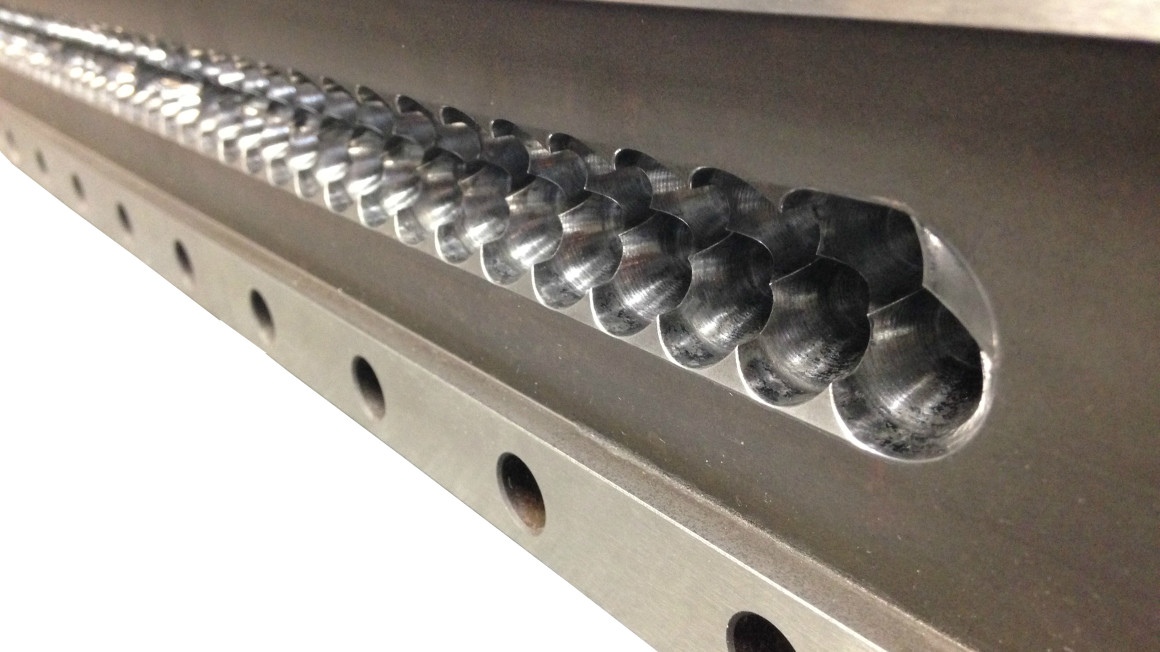

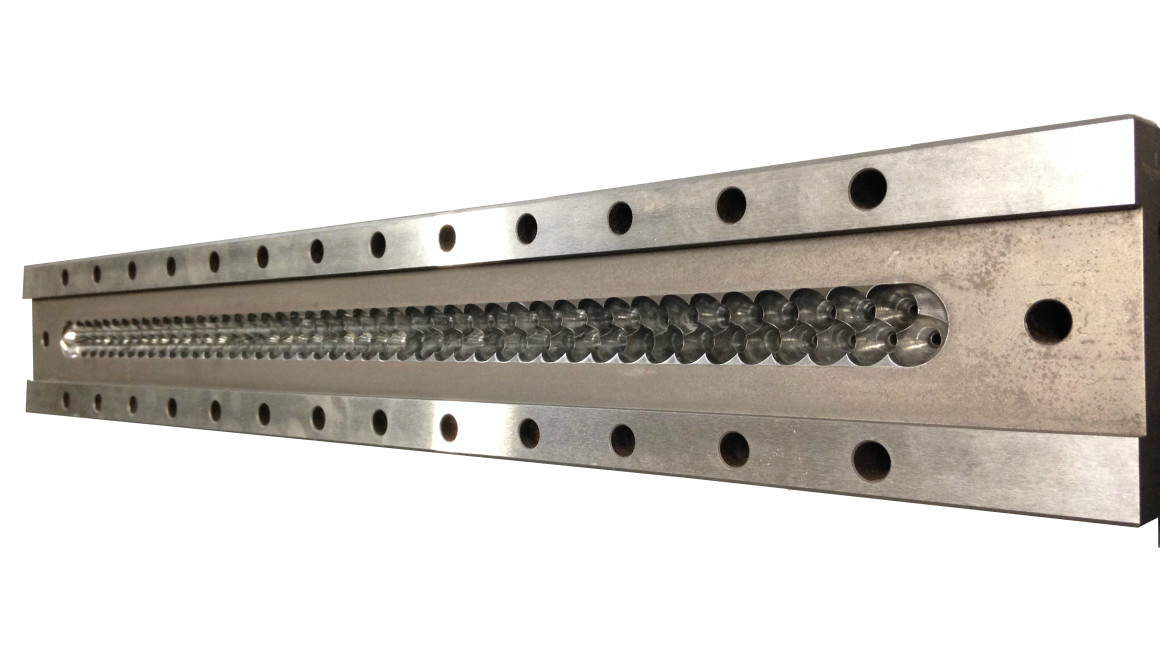

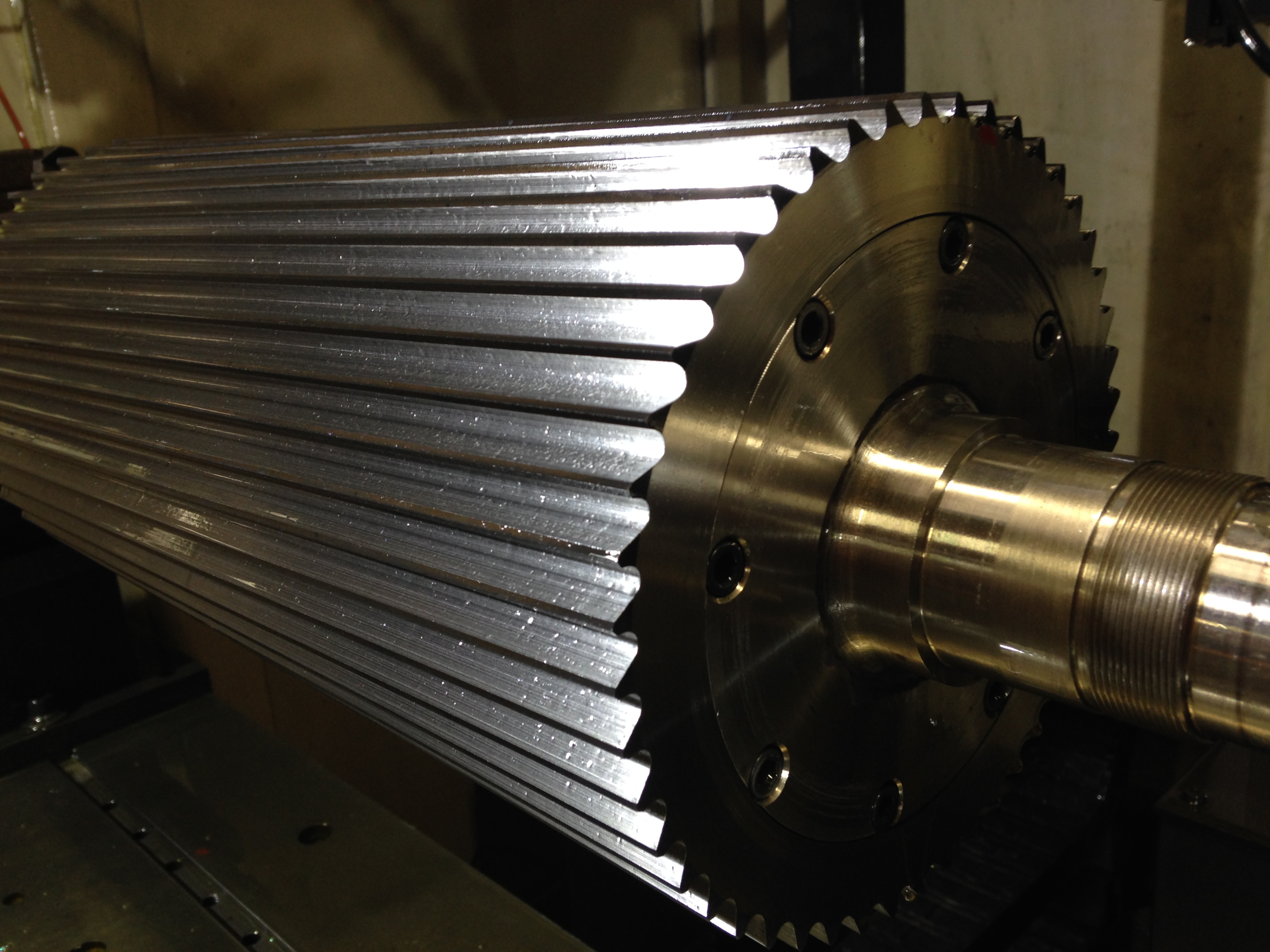

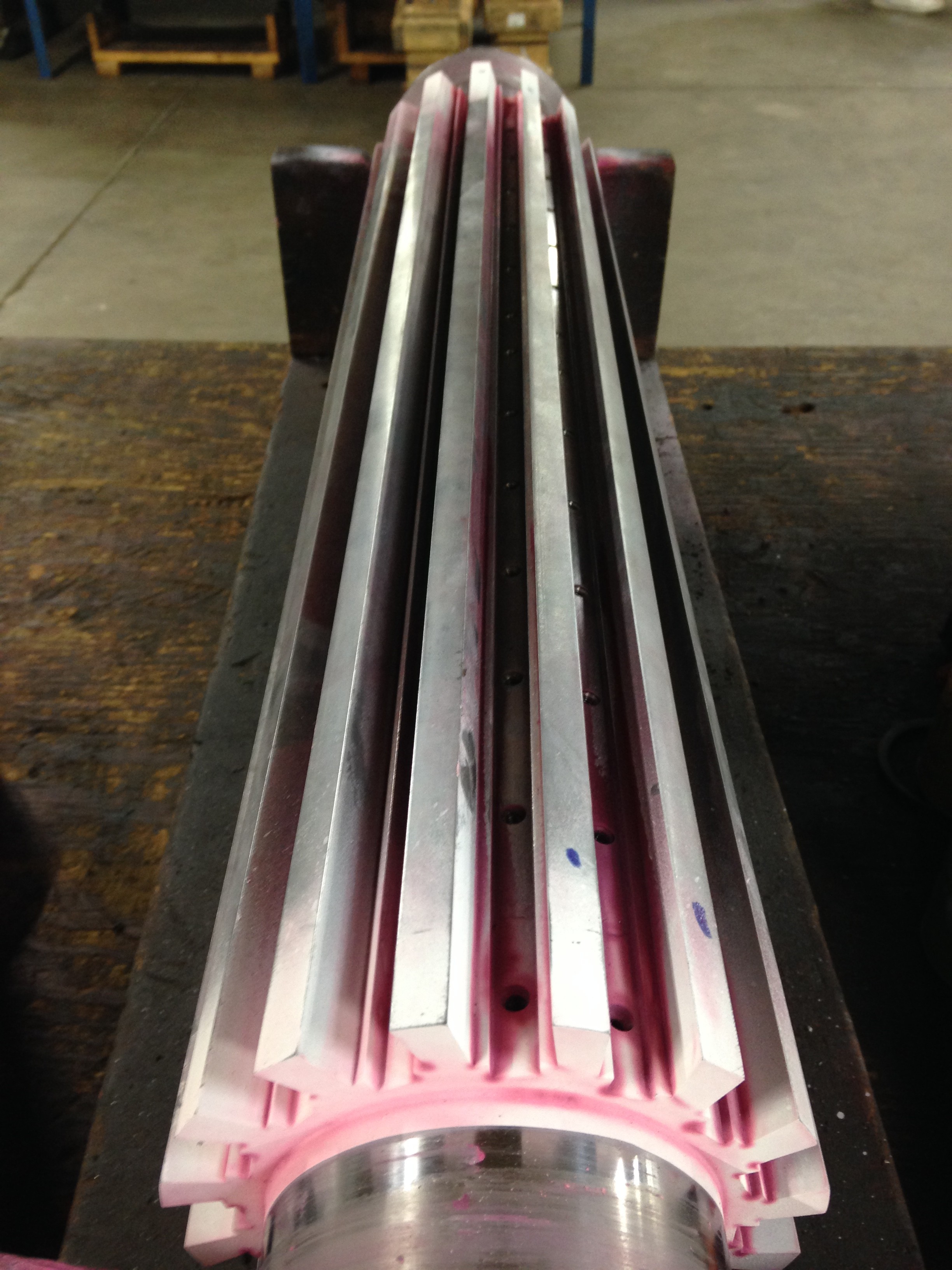

Helical Pelletizer Rotors Find out more

Great Lakes Industrial Knife is an industry leader in the manufacturing and repair of helical pelletizer rotors for all machine makes and models including Conair, Rieter/Automatik, Ikegai and Cumberland. Our skilled machinists and engineers can produce or repair all types of bolt-on, wedge lock, solid head helical pelletizer rotors and bed knives right here in the USA which reduces lead times and transportation costs. Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your helical pelletizer challenges.

Our Helical Pelletizer Rotors are CNC manufactured to extremely close tolerances.

- Bolt-in Helical Pelletizer rotors

- Wedge lock Helical Pelletizer rotors

- Solid head Helical Pelletizer rotors

- Expert in house sharpening service, match ground sets

- CNC sharpening to OEM specs, .0005″ concentricity

- Complete mig weld repairs including bearing journals, eccentrics, rotor bodies & shafts

- Rotor balancing

- Exact tooth profiles – mirror finishes

- Tungsten carbide surface coating

- Bed knives

- Proven extreme condition materials for maximum wearability, toughness and production

Performance Engineered Metallurgy

- High wear alloy tool steels

- D-2 High carbon/High chrome tool steel

- Powdered metals, CPM 10V®, CPM M4®

- High performance stainless steels

- Composite tool steels

- Solid Stellite®

- Inlaid Stellite®

- Zirconia ceramics

- Wc Tungsten Carbide and TiC Titanium Carbide hard metals

- ICE™ Inlaid Carbide Extreme

Stellite® is a registered trademark of Deloro Stellite Company Inc.

Ferro-TiC® is a registered trademark of Pacific Sintered Metals

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Request a Quote

Request a quote form

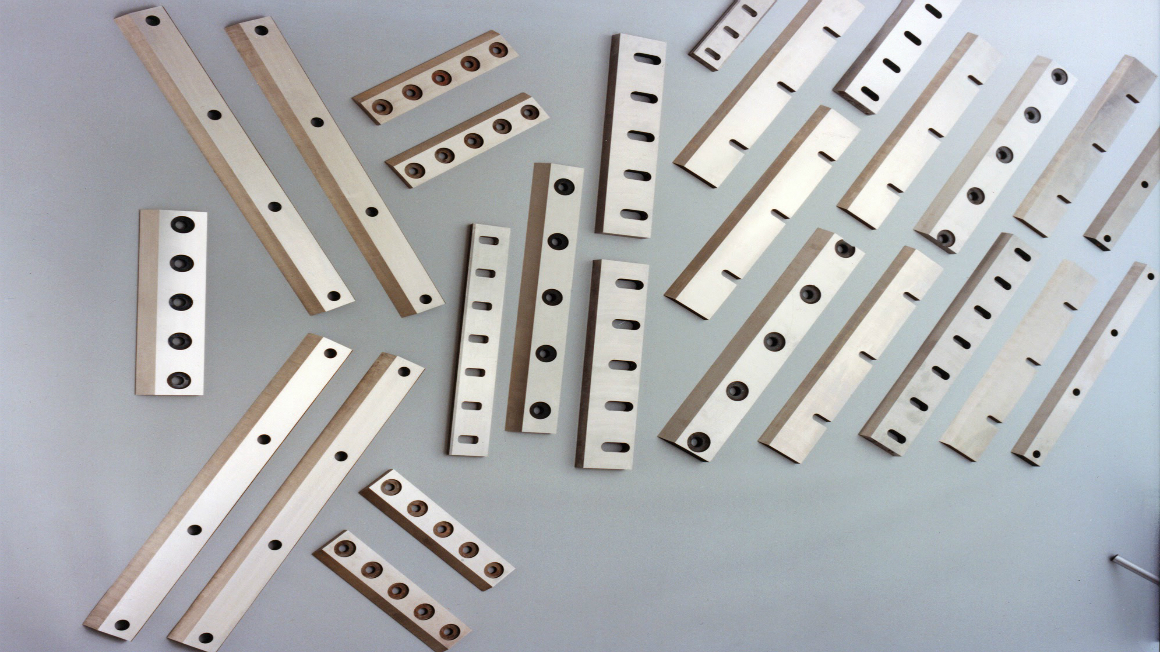

Pelletizer Knives Find out more

Great Lakes Industrial Knife is a leading manufacturer of strand cut and underwater pelletizer knives and dies for virtually all machine makes and models including Beringer, Gala, Conair, Rieter/Automatik, Ikegai and Cumberland as well as many more. Our experienced and skilled engineers and machinists manufacture a wide variety of strand cut pelletizer rotor knives, underwater pelletizer knives, helical pelletizers, bolt-on pelletizer knives right here in the USA! Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your pellet cutting challenges.

All of our Pelletizer knives are precision manufactured to extremely close tolerances.

We also offer pelletizer knife grinding, CNC pelletizer knife sharpening, and pelletizer equipment.

- Under water Pelletizer die face manufacturing, grinding & refacing

- Precision manufactured to extremely close tolerances

- Burr-free razor sharp edges

- Expert in house sharpening service, match ground sets

- Computerized inventory control

- Stock delivery on standard knives

- Proven extreme condition materials for maximum wearability, toughness and production

Performance Engineered Metallurgy

- High wear alloy tool steels

- D-2 High carbon/High chrome tool steel

- Powdered metals, CPM 10V®, CPM M4®

- Composite tool steels

- High performance stainless steels

- Solid Stellite®

- Inlaid Stellite®

- Zirconia ceramics

- Wc Tungsten & TiC Titanium carbide hard metals

- ICE™ Inlaid Carbide Extreme

Stellite® is a registered trademark of Deloro Stellite Company Inc.

Ferro-TiC® is a registered trademark of Pacific Sintered Metals

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Request a Quote

Request a quote form

Pneumatic Air Trim In-Line Chopper Knives Find out more

Great Lakes Industrial Knife Inc manufactures pneumatic air trim in-line granulator rotor and bed knives for all machine makes and models, Including (PAC) Precision Airconvey 78 and (PAC) Precision Airconvey 811, BloApCo (Blower Applications) as well as all others.

Quality replacement knives manufactured to OEM tolerances and specifications and shipped from stock.

| Replacement Knives for PAC Precision Airconvey | GL Part # | |

|---|---|---|

| Tungsten carbide rotor / fly knives for PAC 78 | 87006870B | |

| Tungsten Carbide Bed / Stationary knives for PAC 78 | 87006870C | |

| T-1 Tool steel rotor / fly knives for PAC 78 (out performs D-2 knives 2-3x) | 54006870A | |

| T-1 Tool steel bed / stationary knives for PAC 78 | 54006870E | |

| Tungsten carbide rotor / fly knives for PAC 811 | 87010500A | |

| Tungsten Carbide Bed / Stationary knives for PAC 811 | 87010500B | |

| T-1 Tool steel rotor / fly knives for PAC 811 (out performs D-2 knives 2-3x) | 54010500D | |

| T-1 Tool steel Bed / Stationary for PAC 811 | 54010500E |

Sharpening Service:

Great Lakes Industrial Knife Co. will sharpen and return your in-line cutter/granulator knives in one week or less. All knives are precision sharpened and balanced in matched sets – Call or email for details.

Pulverizer Discs / Pulverizer Plates Find out more

Great Lakes Industrial Knife manufacturers, sharpens and reconditions pulverizer discs and pulverizer plates for all machine makes and models, including Wedco, Orenda, Herbold, RE and many more.

- Precision manufactured to OEM specifications

- Exact tooth profile

- TiN Coating

- Proven extreme condition materials for maximum wearability, toughness and production

Performance Engineered Metallurgy

- High wear alloy tool steels

- High speed tool steel

- Powdered metals, CPM 10v®, CPM M4®

- ™ICE Inlaid Carbide Extreme

Stellite® is Registered Trademark of Deloro Stellite Company Inc.

Ferro-TiC® is a registered trademark of Pacific Sintered Metals

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Score Knives Find out more

Great Lakes Industrial Knife manufactures Score Knives for every paper converting operation and for all machine makes and models including Appleton, Cameron, Coretech & Dusenbery.

All of our Score Knives are precision manufactured to extremely close tolerances to produce razor sharp edges.

- Dust free edge technology

- Mirror bevel finishes – razor sharp custom edge radius

- Available from stock

- Computerized inventory control

- Expert regrind service – match ground sets

- Proven extreme condition materials for maximum wearability and production

Performance Engineered Metallurgy

- Alloy tool steels

- D-2 High carbon/High chrome tool steel

- High speed steels

- High performance stainless steels

- Powdered metals, CPM 10V®, CPM M4®

- Zirconia ceramics

- Solid tungsten carbide

- ICE™ Inlaid Carbide Extreme

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Slitter Anvils / Rolls Find out more

Great Lakes Industrial Knife manufactures hardened & ground Anvils for every paper converting operation.

- Through Hardened Tool Steel

- Flame hardened carbon steel

- Mirror finishes

- Hard Chrome Surface Plating

- Computerized inventory control

- Expert regrind service – match ground sets

- Proven extreme condition materials for maximum wearability and production

Performance Engineered Metallurgy

- Alloy tool steels

- D-2 High carbon/High chrome tool steel

- High speed steels

- High performance stainless steels

- Powdered metals, CPM 10V®, CPM M4®

- Zirconia ceramics

- Solid tungsten carbide

- ICE™ Inlaid Carbide Extreme

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Slitter Knives Find out more

Great Lakes Industrial Knife manufactures and sharpens Slitter Knives for virtually every paper converting operation and for all machine makes and models including Arrow, Arpeco, Cameron, Dusenbery, Goebel, Harris, Stahl, and Tidland. And we manufacture them right here in the USA!

All of our Slitter Knives are precision manufactured to extremely close tolerances to produce razor sharp edges. Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your Slitter Knife challenges.

- Proudly manufactured and sharpened in the USA by skilled machinists

- Leverage our rapid response manufacturing to get your parts in a matter of weeks – not months!

- Dust free edge technology

- Super finished bevels

- Mirror bevel finishes – razor sharp

- Available from stock

- Computerized inventory control

- Expert regrind/sharpening service – match ground sets

- Proven extreme condition materials for maximum wearability and production

Performance Engineered Metallurgy Options Include:

- Alloy tool steels

- D-2 High carbon/High chrome tool steel

- High speed steels

- High performance stainless steels

- Powdered metals, CPM 10V®, CPM M4®

- Zirconia ceramics

- Solid tungsten carbide

- ICE™ Inlaid Carbide Extreme

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Knife-Edges: Regardless of the material being slit, score-cut knives should have rounded edges. Experience may show that other combinations of included angles and edge radii may give more satisfactory results on particular materials. These illustrations, however, should be used as a guide. The cross-sections show the mean radius of each class of edge magnified approximately 60 times.

“A” Edge .002 to .004 Radius

“B” Edge .006 to .008 Radius

“C” Edge .010 to .012 Radius

A – 30° Included Angle

Cellophane • Board Pressure • Sensitive Tape • Cork – Linoleum • Acetate

B – 30° Included Angle

Paper back foil • Waxed paper • Rubber • Plastic (over .01) • Surgical Adhesive • Pulp

C – 45° Included Angle

Waxed paper • Impregnated Paper

B – 60° Included Angle

Gauze • Textiles • Non-woven

B – 45° Included Angle

Glassine • Plastic (to .01) • Tissue • Newsprint • Light Paper • Crepe Paper • Kraft Paper • Mica Tape • Masking Tape

C – 60° Included Angle

Sandpaper • Abrasive Fabrics

Shear Cut: These two illustrations show the cutting edge angles that have been successfully used on converter and mill-type winders. Our specialists will recommend the best cutting edges for particular materials.

30 °

Used on smaller diameter shear-cut knives such as those used on converter type winders.

45 °

Used on larger diameter shear-cut knives such as those used on mill type winders.

Request a Quote

Request a quote form

Slitter Sleeves / Shafts Find out more

Great Lakes Industrial Knife manufactures Hardened and Ground Slitter Sleeves for virtually every paper converting operation. All of our Slitter Sleeves are precision manufactured to extremely close tolerances by skilled and experienced machinists right here in the USA!

Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your strand pelletizer feed roll challenges.

- Proudly made in the USA by skilled machinists

- Leverage our rapid response manufacturing to get your parts in a matter of weeks – not months!

- Through Hardened Tool Steel

- Mirror Finishes

- Available from stock

- Computerized inventory control

- Expert regrind service – match ground sets

- Proven extreme condition materials for maximum wearability and production

Performance Engineered Metallurgy

- Alloy tool steels

- D-2 High carbon/High chrome tool steel

- High speed steels

- High performance stainless steels

- Powdered metals, CPM 10V®, CPM M4®

- Zirconia ceramics

- Solid tungsten carbide

- ICE™ Inlaid Carbide Extreme

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Request a Quote

Request a quote form

Tooth Cut Off Knives / Packaging Knives Find out more

Tooth Cut-Off Knives and Packaging Knives from Great Lakes Industrial Knife are precision manufactured to extremely close tolerances by skilled machinists right here in the USA!

Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your packaging knife challenges.

- Proudly made in the USA!

- Leverage our rapid response manufacturing to get your packaging knives in a matter of weeks – not months!

- Precision manufactured to extremely close tolerances

- Mirror surface finishes

- Form ground tooth profiles

- Burr-free cutting technology

- Short lead times on custom orders

- Proven extreme condition materials for maximum durability

Performance Engineered Metallurgy Options Include:

- Carbon and Alloy tool steels

- D-2 High carbon/High chrome steel

- ICE™ Inlaid Carbide Extreme

Request a Quote

Request a quote form

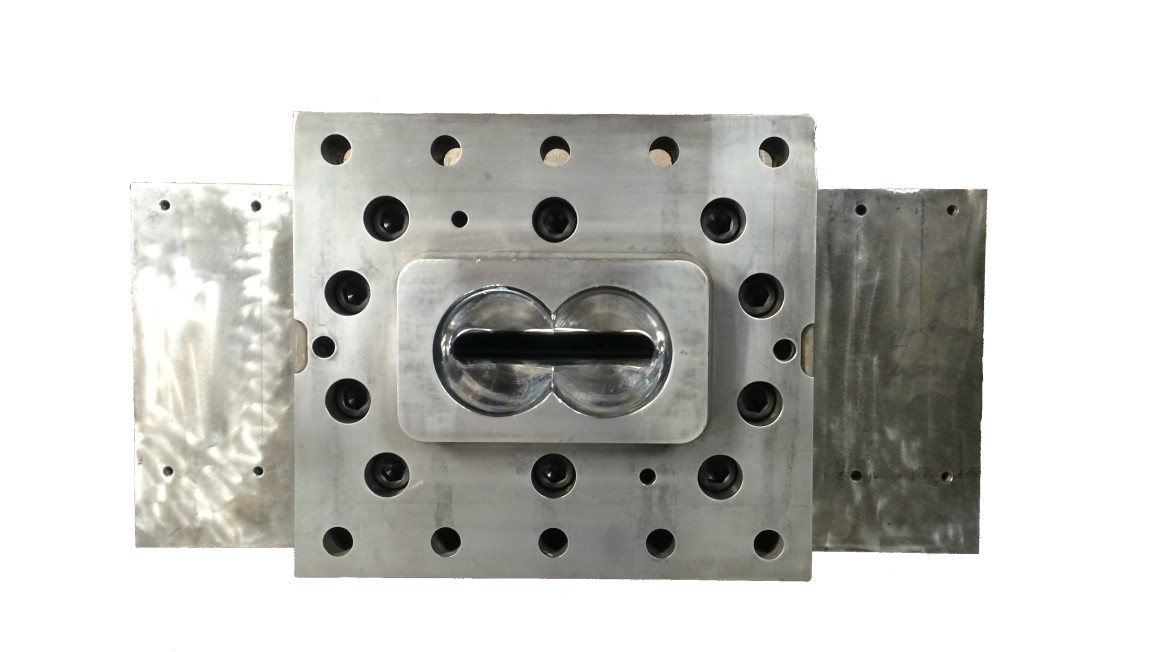

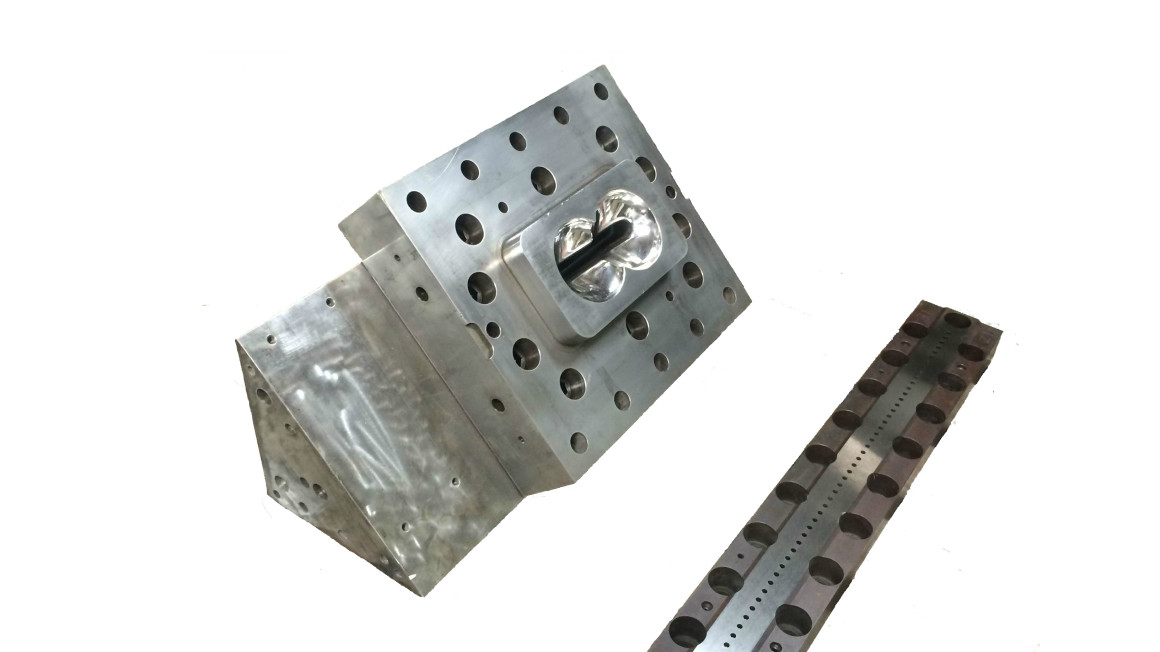

Underwater Melt Cutter Die / Face Resurfacing Find out more

Great Lakes Industrial Knife expertly manufactures and resurfaces Die Plates for all underwater pelletizer machines including Crown/CDL Technologies, Gala, Berstorff, Beringer, Black Clawson, Dynisco, Farrel and Werner & Pfleiderer right here in the USA.

Our skilled engineers and machinists can make or repair virtually every any type of melt cutter die. Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your die plate challenges.

Our Underwater Melt Cutter Die Plates are CNC manufactured to extremely close tolerances.

- Proudly made in the USA by skilled engineers and machinists

- Leverage our rapid response manufacturing to get your parts in a matter of weeks – not months!

- Thru holes wire cut to exact size and profile

- Solid ring hard face construction as well as tiled faces

- Precision ground surface finish

- Mirror super finishing available on die face

- Vacuum bond brazing

- Ceramic die capillary insulation inserts

- Tungsten carbide capillary wear inserts

- Hastelloy® Haynes alloy C-276 insulation rings

- Carbon steel or stainless steel die bodies

Performance Engineered Metallurgy Options

- Wc Tungsten carbide wear surface material

- TiC Titanium carbide Ferro-tic® wear surface material

- Stellite® wear surface material

- Inconel 625

Stellite® is Registered Trademark of Deloro Stellite Company Inc.

Hastelloy® is a registered trademark of Haynes International, Inc.

Request a Quote

Request a quote form