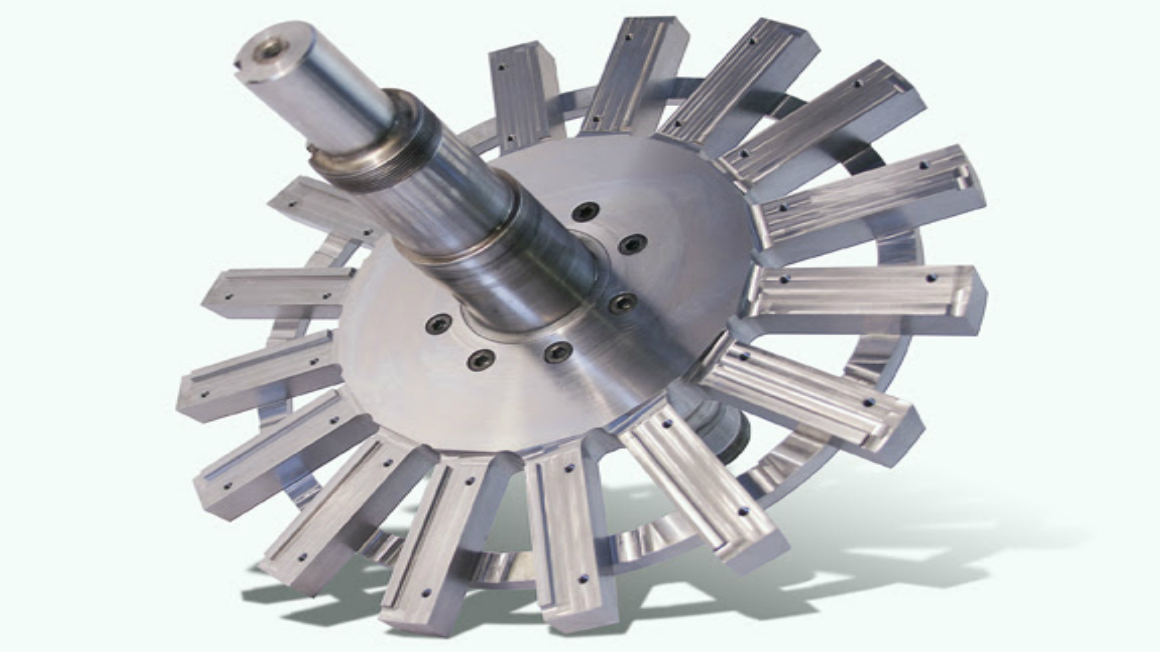

Great Lakes Industrial Knife is recognized throughout the Metal Working Industry as a leading manufacturer of high quality Shear and Rotary Shear blades. Performance engineered, our Shear and Rotary Shear blades meet or exceed OEM specifications.

- High-Tech Metallurgy

- Match ground sets

- Burr free edge technology

- Expert regrind/sharpening service

- Made in the USA

For a quote, Call (888) 665-1200, Fax (330) 665-1204, Contact Us, or Fill out our quote form today!

Product List

Custom Machine Knives Find out more

Great Lakes Industrial Knife is a leading manufacturer of machine knives and blades spanning a multitude of industries and applications. Proudly made in the USA by skilled engineers and machinists, machine knives and blades from Great Lakes deliver the performance and durability you need to keep your plant running. We specialize in quick-turn manufacturing and can produce knives in just weeks. Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your various machine knife challenges.

Our Machine Knives are precision manufactured to extremely close tolerances.

- Short lead time on custom orders

- Expert regrind service

- Made in USA

- Proven extreme condition materials for maximum wearability, toughness and performance

Performance Engineered Metallurgy

- Alloy tool steels

- D-2 High carbon/High chrome tool steel

- High speed steels

- Powdered metals, CPM 10V®, CPM M4®

- Composite tool steels

- High performance stainless steels

- Solid Stellite®

- Inlaid Stellite®

- Zirconia ceramics

- Tungsten Wc & Titanium carbide hard metals TiC Ferro-Tic®

- ICE™ Inlaid Carbide Extreme

Stellite® is Registered Trademark of Deloro Stellite Company Inc.

Ferro-TiC® is a registered trademark of Pacific Sintered Metals

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Request a Quote

Request a quote form

Shear Blades and Rotary Shears Find out more

Great Lakes Industrial Knife manufactures Shear blades and Rotary shears for all machine makes and models as well as custom made to order.

Our Shear Blades and Rotary Shears are precision manufactured to extremely close tolerances.

- Computerized inventory control

- Stock delivery on standard knives

- Short lead times on non stock blades

- Expert in house sharpening service – match ground sets

- Mig weld nick and chip repairs

- Demagnetizing

Performance Engineered Metallurgy

- High shock tool steels

- D-2 High carbon/High chrome tool steel

- ICE™ Inlaid Carbide Extreme

Shear Blades for All Makes & Models

- Chicago

- Hydrapower

- Wean

- Betenbender

- American Hercules

- Pexto

- Amada

- Atlantic

- Pullmax

- Wysong & Miles

- Scottish

- Cleveland Crane

- Darley

- Safan

- Loopco

- Dreis & Krump

- Famco

- Lodge & Shipley

- Accur-Shear

- Niagara

- Edwards / Pearson

- Herr-Voss

- National

- Murata Weidmann

- Gatti

- Rhodes

- Roper-Whitney

- Guifil

- Stamco

- Paxson

- Di-Acro

- Gary

- Cincinnati

- HTC

- Pacific

- LVD

- Summit

- Tennsmith

- Promecam

- Steelweld

- Adira

- Delta Brands

- Morgan

- Welty-Way

- Yoder

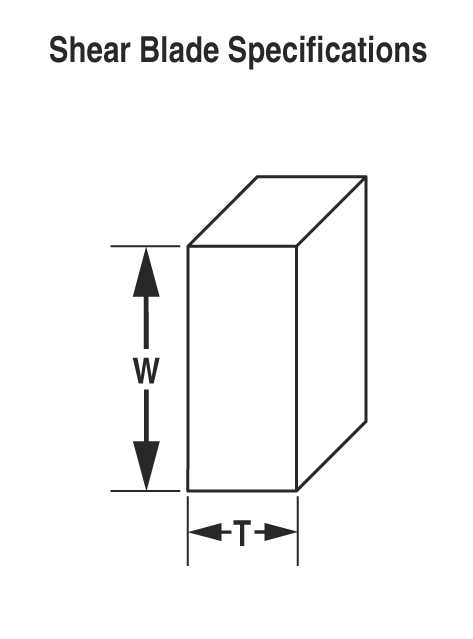

Shear Blades Grinding Limits

| Original Size | Minimum Width (W) | Minimum Thickness (T) |

|---|---|---|

| 3.000 x 1.000 | 2-5/8″ | 3/4″ |

| 4.000 x 1.000 | 3-5/8″ | 3/4″ |

| 5.000 x 1.125 | 4-5/8″ | 7/8″ |

| 5.500 x 1.50 | 5-1/8″ | 1-1/4″ |

| 6.500 x 1.750 | 6-1/8″ | 1-1/2″ |