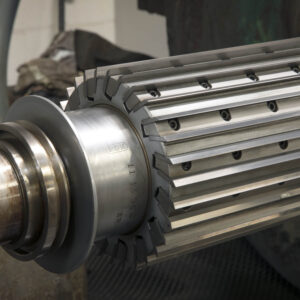

Helical Pelletizer Rotors

Our helical pelletizer rotors are designed to deliver superior performance and durability. Crafted from the highest-grade materials, our rotors ensure optimal cutting efficiency and longevity, reducing downtime and maintenance costs. Each rotor is meticulously engineered to meet the specific requirements of your pelletizing system, ensuring seamless integration and exceptional performance.

- Conair®

- Rieter®/Automatik®

- Ikegai®

- Cumberland®

- And more

- Bolt-in Helical Pelletizer rotors

- Wedge lock Helical Pelletizer rotors

- Solid head Helical Pelletizer rotors

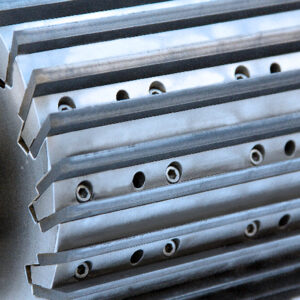

- Expert in house sharpening service, match ground sets

- CNC sharpening to OEM specs, .0005″ concentricity

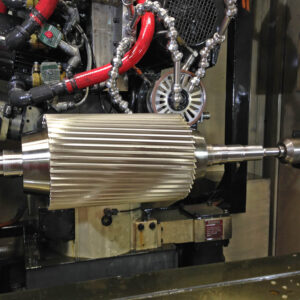

- Complete mig weld repairs including bearing journals, eccentrics, rotor bodies & shafts

- Rotor balancing

- Exact tooth profiles – mirror finishes

- Tungsten carbide surface coating

- Bed knives

- Proven extreme condition materials for maximum wearability, toughness and production

- High wear alloy tool steels

- D-2 High carbon/High chrome tool steel

- Powdered metals, CPM 10V®, CPM M4®

- High performance stainless steels

- Composite tool steels

- Solid Stellite®

- Inlaid Stellite®

- Zirconia ceramics

- Wc Tungsten Carbide and TiC Titanium Carbide hard metals

- ICE™ Inlaid Carbide Extreme

Contact Our Team

Leverage our decades of experience to solve your strand pelletizer feed roll challenges.

Benefits

Maximized Efficiency

- Reduced Downtime: High durability and consistent performance reduce the need for frequent replacements, keeping your operations running efficiently.

- Energy Savings: Our rotors are engineered to require less power during operation, contributing to lower energy consumption and cost savings.

Enhanced Productivity

- Increased Throughput: The efficient cutting action and uniform pellet production lead to higher throughput rates, maximizing your production capacity.

- Improved Product Quality: Consistent pellet size and shape improve the quality of your final product, enhancing customer satisfaction.

Cost-Effective Operation

- Long Service Life: With superior materials and precision engineering, our rotors offer a longer service life, reducing the overall cost of ownership.

- Minimal Maintenance: Designed for easy maintenance and replacement, our rotors help you minimize maintenance costs and downtime.

Why Choose Great Lakes Industrial Knife?

Industry Expertise

With decades of experience in rotor manufacturing, we understand the challenges of pelletizing and offer solutions that meet the highest standards of performance and reliability.

Customer-Centric Approach

We work closely with our customers to understand their unique needs and provide tailored solutions that enhance their operational efficiency and productivity.

Made in the USA

Our skilled machinists and engineers can produce or repair all types of bolt-on, wedge lock, solid head helical pelletizer rotors and bed knives right here in the USA, which reduces lead times and transportation costs.

Key Features

Advanced Helical Design

- Optimized Cutting Performance: Our helical design ensures smooth, consistent cutting action, reducing wear and tear on both the rotor and the die plate.

- Enhanced Pellet Quality: Achieve uniform pellet size and shape for superior downstream processing and product quality.

Superior Materials

- High-Grade Steel Construction: Crafted from premium, wear-resistant steel, our rotors offer extended service life and exceptional durability.

- Corrosion Resistance: Special coatings are available to provide additional protection against corrosive materials, ensuring long-term operational integrity.

Precision Manufacturing

- Tight Tolerances: Manufactured to exacting tolerances, our rotors deliver precise and repeatable performance, minimizing downtime and maintenance costs.

- Custom Solutions: We offer custom rotor designs tailored to your specific needs, ensuring optimal performance in any application.