Pelletizer Knives

Great Lakes Industrial Knife manufacturers high-performance pelletizer knives that are crafted with the utmost precision and engineered for durability, ensuring that your operations run efficiently and produce the highest quality pellets.

OEM Compatibility

- Egan™

- Erema™

- Ettlinger™

- Farrel™

- Gala™

- JSW™

- Kobe™

- BKG™

- Black Clawson™

- Buss™

- Conair™

- Condux™

- Coperion™

- Crown™

- NGR™

- PTI™

- Werner Pfleiderer™

- AST™

- Automatik™

- Beringer™

- Berstorff™

- and more!

What Sets Our Pelletizer Knives Apart

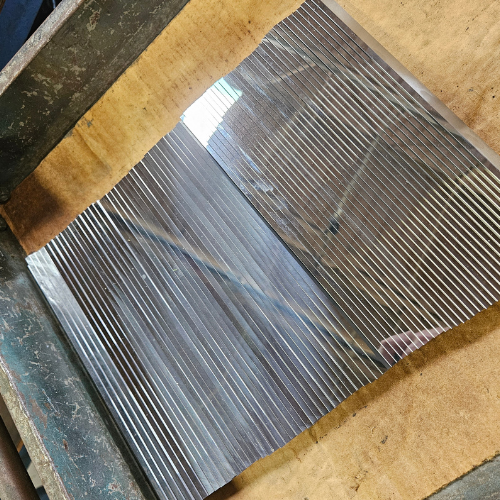

Manufactured to Tight Tolerances

All pelletizer knives are precision manufactured to extremely close tolerances for consistent, clean cuts and uniform pellet size and quality.

- Underwater pelletizer die face manufacturing, grinding, and refacing

- Burr-free, razor-sharp edges

- Expert in-house sharpening service with match-ground sets

- Precision mirror finish

- CNC pelletizer knife sharpening

- Computerized inventory control

- Stock delivery on standard knives

- Proven extreme condition materials for maximum wearability, toughness, and production

Contact Our Team

Leverage our decades of experience to solve your strand pelletizer feed roll challenges.

Performance Engineered Metallurgy

Our pelletizer knives utilize advanced materials to ensure superior performance and longevity, including:

- High wear alloy tool steels

- D-2 high carbon/high chrome tool steel

- Powdered metals (CPM 10V®, CPM M4®)

- Composite tool steels

- High-performance stainless steels

- Solid Stellite® and Inlaid Stellite®

- Zirconia ceramics

- Wc Tungsten

- ICE™ Inlaid Carbide Extreme

Key Features

Premium Material Construction

- High-Quality Steel: Our pelletizer knives are made from premium-grade steel, ensuring exceptional strength, durability, and wear resistance.

- Advanced Coatings: Available with specialized coatings to enhance cutting performance and extend the lifespan of the knives, reducing maintenance needs and downtime.

Precision Engineering

- Exacting Tolerances: Manufactured to precise tolerances, our knives deliver consistent and clean cuts, ensuring uniform pellet size and quality.

- Custom Designs: We offer customized knife designs tailored to your specific pelletizing needs, providing optimal performance for various materials and applications.

Benefits

Consistent Quality

Our precision-engineered pelletizer knives ensure uniform pellet production, reducing waste and improving overall product quality.

Increased Throughput

Superior cutting performance allows for higher production speeds, maximizing your output and efficiency.

Why Choose Great Lakes Industrial Knife?

Industry Expertise

With decades of experience in pelletizer knife and rotor manufacturing, we understand pelletizing challenges and deliver solutions that meet the highest standards of performance and reliability.

Customer-Centric Approach

We work closely with you to provide tailored solutions that enhance operational efficiency and productivity.

Made in the USA

Our skilled machinists and engineers produce and repair all types of bolt-on, wedge lock, and solid head helical pelletizer rotors and bed knives in the USA, reducing lead times and transportation costs.

Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your strand pelletizer rotor challenges.

Stellite® is a registered trademark of Deloro Stellite Company Inc.

Ferro-TiC® is a registered trademark of Pacific Sintered Metals

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

What are pelletizer knives used for?

Pelletizer knives are precision-engineered blades utilized in pelletizing systems to cut molten plastic into uniform pellets. These knives are essential in various applications, including plastic recycling, virgin resin production, compounding, and masterbatch manufacturing, ensuring consistent pellet size and quality.

How do you maintain pelletizer knives?

Keep knives sharp by inspecting and replacing blades as needed, cleaning the cutting area, and ensuring proper alignment in the pelletizer. Proper maintenance prevents uneven cuts, reduces stress on equipment, and improves overall efficiency.

How long will pelletizer knives last?

Blade life depends on material, feedstock, and operating conditions. High-quality knives can last much longer than standard blades, sometimes multiple production runs, while maintaining clean cuts and minimizing waste. Regular inspection and proper maintenance help maximize lifespan.

Do you offer repair or refurbishment for pelletizer knives?

Yes. We provide blade refurbishment, sharpening, and reconditioning services to restore performance and extend service life, helping you avoid unnecessary replacements and minimize downtime.

What is the lead time for pelletizer knives?

Standard pelletizer knives are often available from stock and can ship quickly. Custom knives typically have short lead times thanks to our in-house design and manufacturing capabilities. Lead time depends on knife type, material, and order volume, but we work to keep downtime to a minimum for every customer.

How does knife design affect pellet quality?

The angle, thickness, and edge profile of pelletizer knives directly influence pellet size, uniformity, and surface finish. Custom knife designs can optimize performance for your specific material and pelletizer setup, ensuring consistent, high-quality pellets.